By Liz Stinson

Each chair is comprised of hundreds of different parts that come together to form a whole.

JORIS LAARMAN DOESN’T work out of a studio so much as a laboratory. The Dutch designer, probably best known for his chair that mimics the growth of human bones, has always claimed dual citizenship in the worlds of classic design and science. “I like to take things out of the scientific world and create something beautiful with it,” he says one day walking around the Friedman Benda Gallery in New York City.

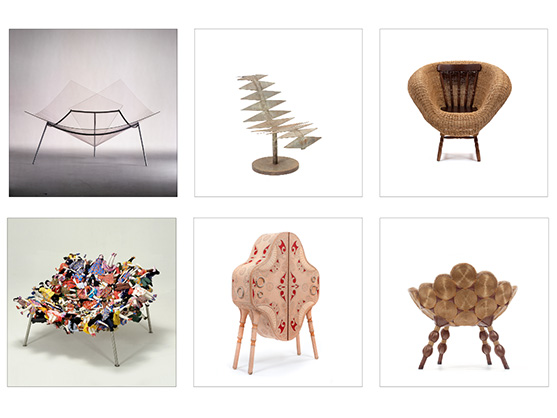

Laarman recently opened up a new exhibition at gallery called Bits and Crafts. And much like his Bone Chair, the new works have an interesting, quasi-craftsmanship aesthetic to it, as though they were born from an affair between a carpenter and a computer scientist.

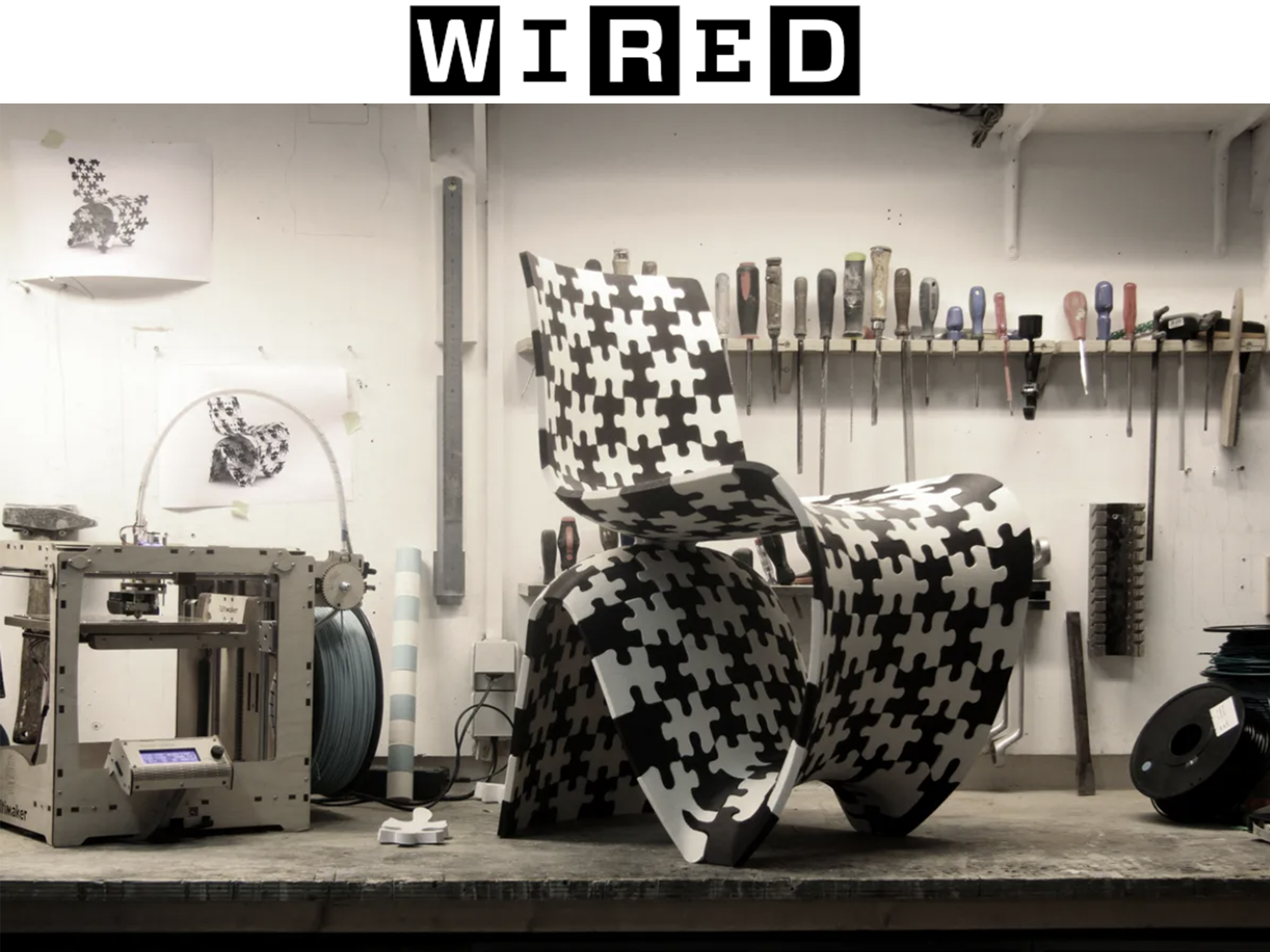

The centerpiece of the show, the Maker Chairs, is one of Laarman’s most ambitious projects yet: A set of algorithmically-designed chairs that can be printed out and constructed like a puzzle. The furniture looks vaguely like Verner Panton’s injection-molded chair from 1960 if it were reimagined by mathematicians.

Each chair is comprised of little bits of material that come together to form a whole. “You can make that yourself for less than $30,” he says, pointing at a black and white version. That one’s made from 77 ABS plastic pieces (the same material that’s used in Legos) that have been snapped together. It’s surprisingly sturdy. “It doesn’t have any glue and you can sit on it.”

At the exhibition, a few chairs down is another made from more than 300 CNC-milled pieces of walnut that have been glued together with epoxy to form a perfectly-smooth geometric pattern. “This one was a little more complicated,” he says. Other variations include a chair made from milled resin and oak, another from hundreds of aluminum bits that hook together.

Open Source Design

The big goal, says Laarman, is to democratize design by making the blueprints available online. He already has a website up; you just have to download the blueprints, take them to a local fabricator and you’ll have a full-sized chair in about 10 days. This idea dates back to the early 20th century, when modernist designers used to make blueprints and manuals available. “I don’t think in the future people will actually make their own chairs if its not super simple,” he says. “But these are simple.”

The Maker Chair project was born out of a simple question: How can we push the boundaries of digital fabrication forward? “We started by thinking, how can we make something relevant, for this time?” he says. “We want to experiment with what’s possible with the technology right now, and maybe just beyond what’s possible.”

Laarman employs two full-time researchers at his lab in Amsterdam, whose job he describes as: “Just playing around with digital fabrication techniques that don’t exist yet.” This has led him to discoveries like the MX3D-Metal Printer, a robotic arm connected to a MIG welding machine that prints metals like steel, aluminum, bronze and copper on demand. Watching the MX3D work is mesmerizing, almost like watching black snake fireworks expand, except Laarman’s output doesn’t crumble into ashes when touched. “We’ve gotten a lot of interest from construction companies and shipyards,” he says.

It’s a totally new way of fabricating that Laarman believes could eventually disrupt the traditional systems of design and making. Being able to fabricate your own objects, especially once 3-D printers scale up in size, will change the way goods are designed, distributed and bought. This is all in the future, Laarman clarifies. For now, it’s best expressed through art. “This is definitely an experiment,” he says. “We’re still in the process of figuring out what’s going to work.”