By Nina Azzarello

founded in 2004, amsterdam-based joris laarman lab is a self-described ‘experimental playground’ that blends cutting-edge technology with traditional means of making. from sculptural furniture to innovative production processes and museum installations, the studio often spends years on a body of work that thematically explores a manufacturing technique, material or technological process.

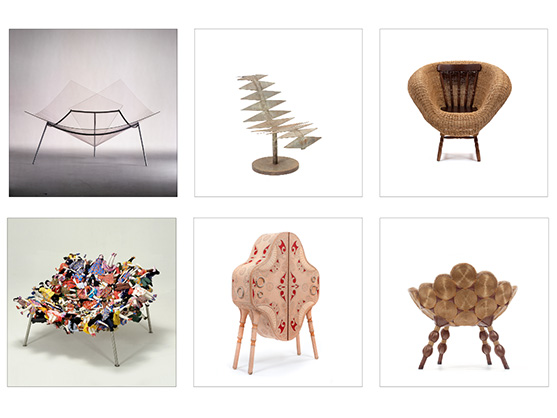

at design miami/ basel 2016, friedman benda gallery presents a survey of laarman’s research in digital fabrication. the exhibition ‘bits & crafts’ includes work from the lab’s ‘microstructures’, ‘dragon bench’, and ‘maker’ series, as well as the debut of the first piece in a new series of robotically printed screens.

the exhibition brings a range of laarman’s series together, each investigating a type of material and methodology. ‘microstructures’ explores 3D printing in durable mediums at the scale of furniture, with each piece made up of cells that vary in form, size and function. ‘dragon bench’ is built by a robotic arm and welding machine that prints stainless steel mid-air, allowing laarman to draw complex curved lines and surfaces in space. works in the ‘maker’ series are built from many parametric parts engineered to fit together exactly like a three-dimensional puzzle. finally, the ‘butterfly screen’ — presented by friedman benda for the first time — forms a 2×3 meter double curved bronze surface based on a hexagonal cell division.

to learn more about the survey at design miami/ basel, designboom spoke with laarman who discussed his creative process, and his thoughts on the evolution of digital fabrication.

designboom: what are some of the key themes of ‘bits & crafts’ at design miami/ basel that connect the exhibit conceptually?

joris laarman: the entire expo is about the symbiosis between digital fabrication and handcraft like the title explains. all pieces explore digital fabrication in a different way; technical as well as in form language, all resulting in functional objects. the microstructures series is conceptually based on 3D gradient patterning and explores intricate 3D printing in durable materials at the scale of furniture. each of these works is built up out of cells that vary in form, size or function.

For the dragon bench, we equipped a robot arm with a welding machine that prints stainless steel mid-air, allowing us to draw complex curved lines and surfaces in space. in 2015 we started a new company around the robotic 3D printing called MX3D. this company is fully focusing on developing robotic 3D printing technology. the maker series hexagon table set is built from many parametric walnut wood parts that are engineered to fit together exactly like a three-dimensional puzzle. debuting in basel is our first large scale robotic printed bronze work.

DB: can you tell us about the new series of robotic printed screens you’re presenting?

JL: our latest experimental work is a collection of sculptural screens, produced by MX3D, varying in sizes, geometries and materials. even multi-material gradients from bronze to steel are in the planning. the computational generated aesthetics of the screens are not just pleasing for the eye, but are also pushing the boundaries of our technology. 3D printing in metals on this large scale is unexplored territory so we are learning as we develop new sculptural work. for every new form language a specific strategy is developed, resulting in large a library of strategies that will become self-learning in the near future. the butterfly screen is a 2 x 3 meter double curved bronze surface based on a hexagonal cell division.

DB: what are the specific technologies employed in its realization?

JL: the basic idea is similar to how we created the first dragon bench. its a robotic arm equipped with a high tech welding machine. but this time we wanted to explore the printing of large curved surfaces. it involved a lot of programming as well as material studies. we have to program the CAD files describing the geometry as well as the robotic kinematics in combination with the welding settings like wire feed, speed and waiting time specific for 3D printing in bronze. every metal works in a different way so we have to develop a library of settings for each specific geometry in combination with a material.

DB: in what ways does the screen series relate to — or differ from — your previous studies?

JL: all studies are a learning experience. printing a large curved surface is a completely different process compared to printing a structure of lines. also, combinations of different morphing geometries are very interesting to test. we can, for instance, start printing a surface in steel that slowly transforms into a line structure of bronze. every work we’ll make will deliver a lot of new data. all together they will eventually result in a self learning adaptive fabrication tool.

DB: how has your experimentation with different materials informed your practice overall?

JL: we like to be diverse in the materials we use. digital fabrication to me is not about 3D printing as most people know it. its a much larger theme. by using such a large variety of materials we show that its not limited to plastic little gadgets. each material asks for a different approach. I personally like our soft gradient chair a lot for instance as its function changes where its cells change in form. where the cells are closed it is rigid and constructive and where its cells are more open it becomes more comfortable. working in wood is a completely new world again, but just as great to be working with such a variety of materials.

DB: in general, where do you see the ‘digital revolution’ heading?

JL: I would rather call it an evolution. things go much slower compared to developments in software, because physical materials take time. the transition from analog to digital has fundamentally changed many aspects of our lives from computing to social media in the last decades. in the early 20th century, modernist pioneers valued and changed notions about aesthetics inspired by emerging industrial manufacturing methods.

Now, the digital revolution has begun to define an evolution in the way physical objects are designed, manufactured, distributed, protected, and recycled. the realm of digital design tools and digital fabrication is shifting everyone’s ideas on design and pushes our lab to explore the endless new possibilities of the digital revolution. at this moment we are finalizing the design for the bridge, that we will start printing in september with MX3D. we are extremely excited to be working in such a disruptive time.